KowCo GasiLamp

GasiLamp is the first of, hopefully, a series of gasifiers I make. This design is intended to prove out the combustion chamber and other aspects of building something like this in my home shop. The gas is developed and will be sent through a filtering system to a set of nozzles. Each nozzle will have a mantle, like a camping lantern. Most gasifiers are attached to a engine which will draw the gas into it, A lamp has no active vacuum system. To get the gas flowing I am adding an alpha class Stirling engine to run the blower. The thought is that the heat generated by the combustion can run the hot cylinder of the engine. I have used a lot of information I have found on the Northern Self Reliance site. The man there, Stephen I think, does a great job of explaining the various parts and principals. Much of my work follows his line of reasoning and prior work.

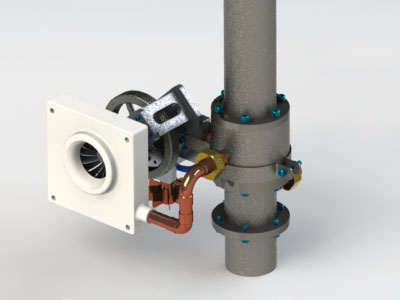

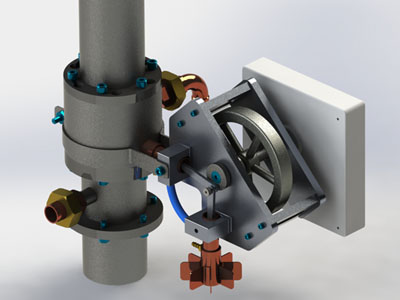

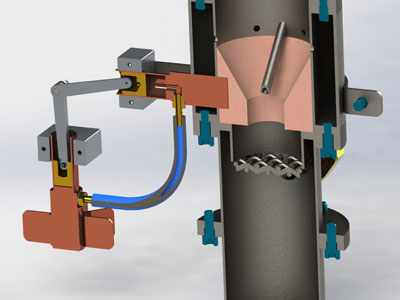

Here is a rendering of the basic setup of the gasifier, mostly of the air intake.

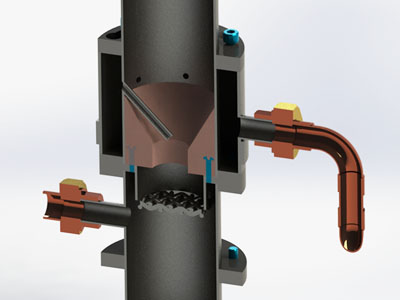

A crossection view of the combustion chamber and air pre-heater plenum.

The Stirling engine. That is the cold side cylinder with the fins. The hot side is embedded in the combustion chamber.

OK so here is how it is embedded in. The light red area is high temp refractory mortar. It is cast with the various holes and shapes needed.

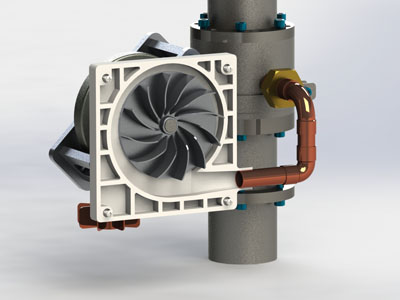

This is a custom blower I designed to fit the system. Solidworks is a great program. It will be 3D Printed in plastic. If this all works out I plan on sand casting these parts in my future little foundry.